REOVIB Measuring equipment

Measuring equipment for vibratory conveyors

Certifications

REOVIB Measuring equipment

Measuring equipment for vibratory conveyors

Description

The REOVIB Testbox 122 is designed to provide accurate indications of voltage and current, when servicing and testing vibratory conveyors. The devices are fitted with moving-iron meters and external connectors are provided to allow fast and safe connection of the feeder and controller.

The REOVIB SWM 4000 handheld measurement unit is used to set up, test and service vibratory conveyor equipment. As a battery powered hand-held device, it is particularly suited for mobile work. Frequency [Hz], vibration amplitude [mm], vibrational velocity [cm/s] and vibrational acceleration [g] can be measured with an acceleration sensor. The values are indicated on the integrated LCD display is and can also be stored in the equipment (40 measured values). The integrated USB interface can transfer this saved data to a PC, within a file, for further analysis.

The REOVIB SWM 1000 sensor is designed to monitor vibratory feeders. The sensor measures the acceleration of a magnetically or motor driven vibrating feeder and supplies 0 (4)… 20 mA outputs for vibrational acceleration [g] and vibration amplitude [mm]. The output of the sensor can be connected directly to a measuring instrument (with 0 (4)… 20 mA input) or to a PLC controller for evaluation or monitoring.

The REOVIB 6050 workshop device contains a REOVIB MFS frequency controller for vibratory conveyors and has been specially developed for use in servicing, construction and design of vibratory conveyors. For rapid control, the desired value of vibration amplitude is adjustable by means of a potentiometer and an integrated ammeter provides indication of the feeder running current.

REOVIB 6100 workshop and diagnostic unit is a microprocessor-controlled device. An integrated REOVIB MFS frequency units controls the feeder, while simultaneously determining vibration frequency [Hz], vibration amplitude [mm], vibrational velocity [cm/s] and vibrational acceleration [g]. The values are shown on the integrated LCD display and can also be stored in the equipment (40 measured values). The integrated USB interface can transfer this saved data to a PC, within a file, for further analysis. The operating frequency of the conveyor can be set manually or can be determined independently using a vibration amplitude sensor with an automatic frequency search.

The REOVIB SWM 843 monitoring device measures and displays the vibration performance of vibratory feeders. The vibration is monitored using an accelerometer and the instantaneous measured values are indicated on the five-digit seven-segment display, as a value of acceleration [g], vibration amplitude [mm] or vibration frequency [Hz]. The acceleration value is also provided as a 0 (4)… 20 mA analogue output for direct connection to a measurement instrument, or for connection to an external measurement device e.g. a PLC controller for evaluation or monitoring.

The REOVIB BK 032 is a monitoring device which measures the vibration behaviour of vibratory feeders. This evaluation device when used in conjunction with an acceleration sensor, allows an acceptable window of operation to be established using adjustable maximum and minimum limits. If operation outside of this window occurs, which could signal a mechnical problem for example, a associated relay switches over which can be used to trigger an external alarm.

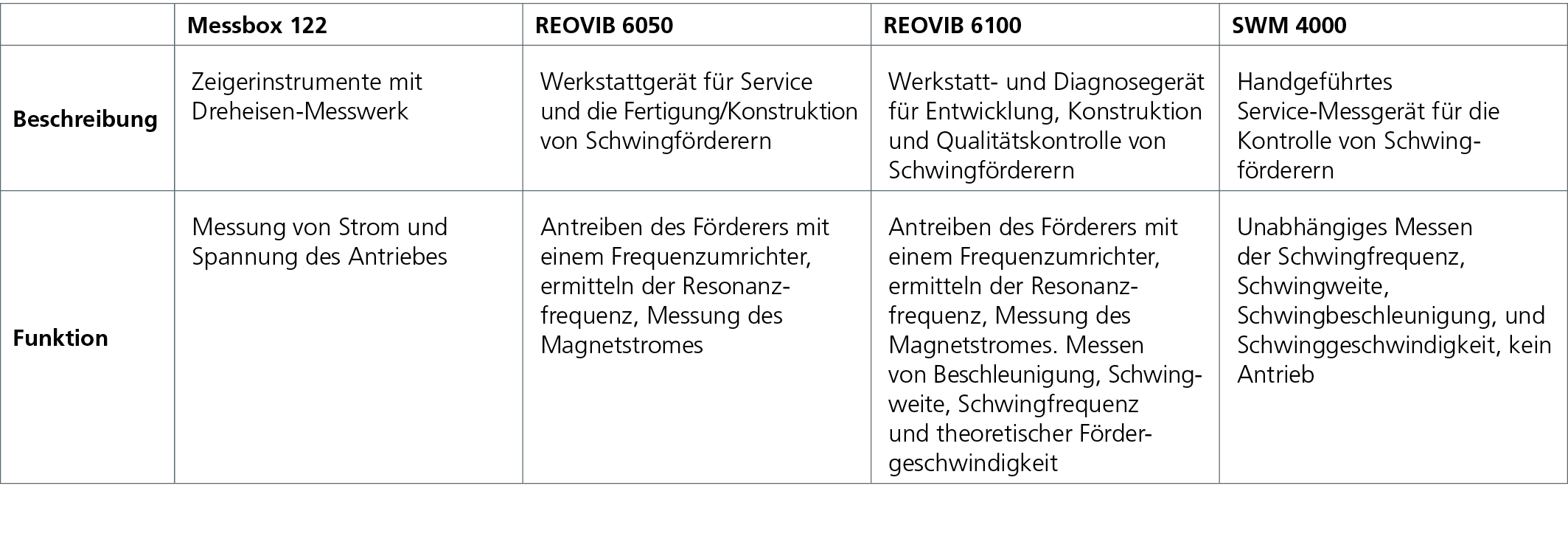

Our measuring equipment

- Testbox 122: Analog measurement instrument for testing vibratory conveyors.

- REOVIB 6050: Workshop equipment for assistance with development / design in the construction of vibratory conveyors.

- REOVIB 6100: Workshop and diagnostic unit for development, construction and quality control of vibratory conveyors.

- REOVIB SWM 4000: Handheld instrument for testingvibratory conveyors.

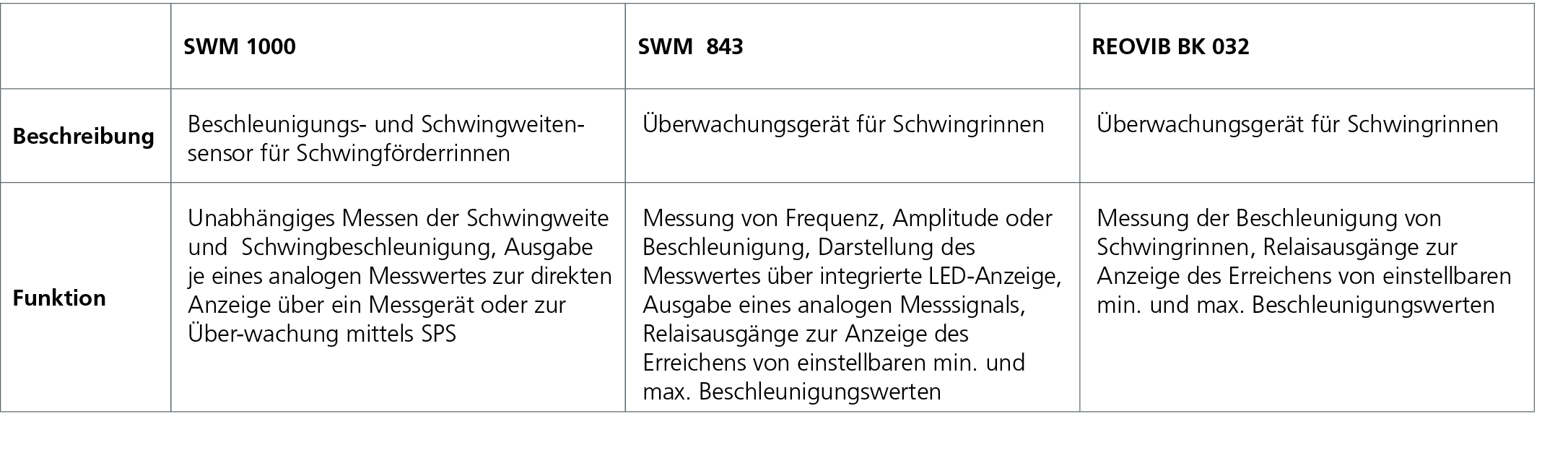

- REOVIB SWM 1000: Acceleration and vibration amplitude sensors for vibratory conveyors.

- REOVIB SWM 843: Monitoring device for vibrating feeders.

- REOVIB BK 032: Monitoring device for vibrating feeders.

Technical specifications